3D printers

Four 3D printers are available for use in SMRL.

Makerbot 2

The MakerBot 2 is a fused deposition modeling (FDM) 3D printer with one extruder. The 3D printer works by extruding thermoplastic filaments, such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), and flexible filament (e.g., thermoplastic polyurethane) through the heated extruder, melting the material and applying the plastic layer by layer to a build platform. Each layer is laid down one at a time until the part is complete. The printer is optimized with PLA printing. The build space for MakerBot 2 is 28.5 x 15.3 x 15.5 cm. The printer offers a layer height resolution of 100 micron to 300 micron, a positioning precision of 2.5 micron on z-direction and 11 micron on the x- and y- axes.

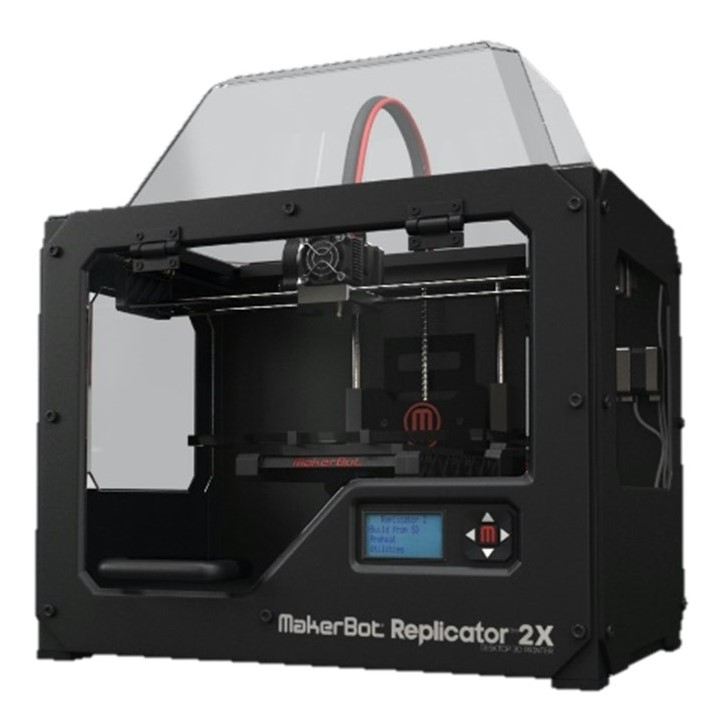

Makerbot Replicator 2x

The MakerBot Replicator 2X 3D printer provides access to experimental, dual-extrusion 3D printing. Both extruders are compatible PLA, ABS, and flexible filament. It is optimized with ABS printing. The printer has a build volume of 24.6 x 15.24 x 15.5 cm. MakerBot Replicator 2X features a six-sided enclosure and a heated aluminum build plate, which helps to get more reliable prints. The Replicator 2X has a 100-micron layer resolution, 11-micron position precision in the x- and y- directions, and 2.5-micro position precision in the z-direction

Formlabs Form 1

The Form 1 prints objects by way of stereolithography (SLA). It uses an ultraviolet laser (with wavelength = 405 nm) to cure photopolymer resin. The laser beam draws a pre-programmed shape on the surface of the photopolymer tank and the photopolymer hardens when it contacts the ultraviolet light. The layer resolutions of the printer can be chosen from 25 microns, 50 microns or 100 microns. The position precision in the x-, y- and z- directions is 25 microns.

Longar Orange 10

The Longer Orange 10 print object use digital light processing (DLP) method, which cures a photopolymer resin with a light beam. The printer uses a projector as a light source and has an 11.5-cm liquid crystal display (LCD) panel in between the projector and the resin tank. Each pixel in the LCD panel either let the light pass or block the light; thereby, cure the resin into the pre-programmed shape. The printer can have 32 parallel lights at the same time. Thus, the printing speed is faster than an SLA printer. Photopolymer resin that can be cured with light having a wavelength of 405 nm. The printing space for this printer is 9.8 x 5.5 x 14 cm. The layer resolution is from 20 microns to 100 microns. The position precision in the x- and y- directions is 115 microns, and position precision in the z-direction is 0.625 microns.