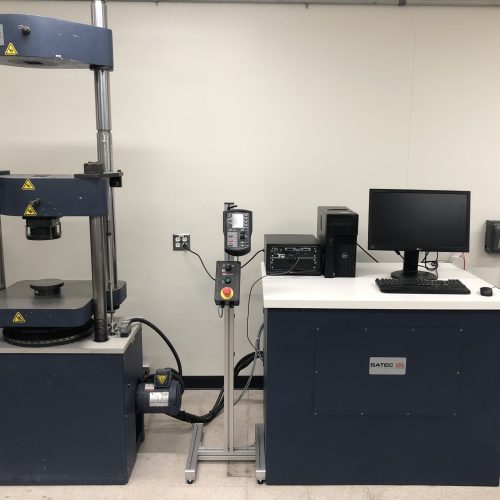

Materials testing space

As seen on the right, the materials testing area houses the following equipment for characterization of the thermo-mechanical properties of materials:

- A static servo-hydraulic SATEC universal testing machine (UTM) for tension/compression testing with 600 kips load capacity and 6 inch stroke (SATEC model 600HVL UTM).

- A static servo-hydraulic SATEC frame for compression testing only with 1,000 kips load capacity and 6 inch stroke (SATEC model 1000 Prism).

- A dynamic servo-hydraulic MTS frame for tension/compression testing with 110 kip load, 6 inch displacement and 30 gpm flow capacity. This load frame is also equipped with an environmental chamber for thermo-mechanical testing of materials (MTS 651.06E-04). The environmental chamber has internal dimensions of 14 x 17 x 32 inches (W x D x H) and a temperature range from -200°F to 600°F.

- A dynamic servo-hydraulic MTS universal testing machine for tension/compression/torsion testing with 22 kips load and 10,000 lbf-in torque capacity, and 6 inch stroke.

Additionally, the following load frames are available to the researchers in the materials teaching laboratory, which is not directly a part of SMRL.

- A static servo-hydraulic SATEC universal testing machine for tension/compression testing with 135 kips load capacity and 6 inch stroke (SATEC model 135HVL UTM).

- A static electro-mechanical Instron load frame for tension testing with 1.1 kips load capacity and 54 inch stroke (Instron model 5965). This load frame is also equipped with an advance video extensometer (Instron 2663-821), which is a high-performance, non-contacting sensor. The video extensometer has a resolution of 0.5 µm, an accuracy of ±2.5 µm and a data rate of 50 Hz.