Facilities

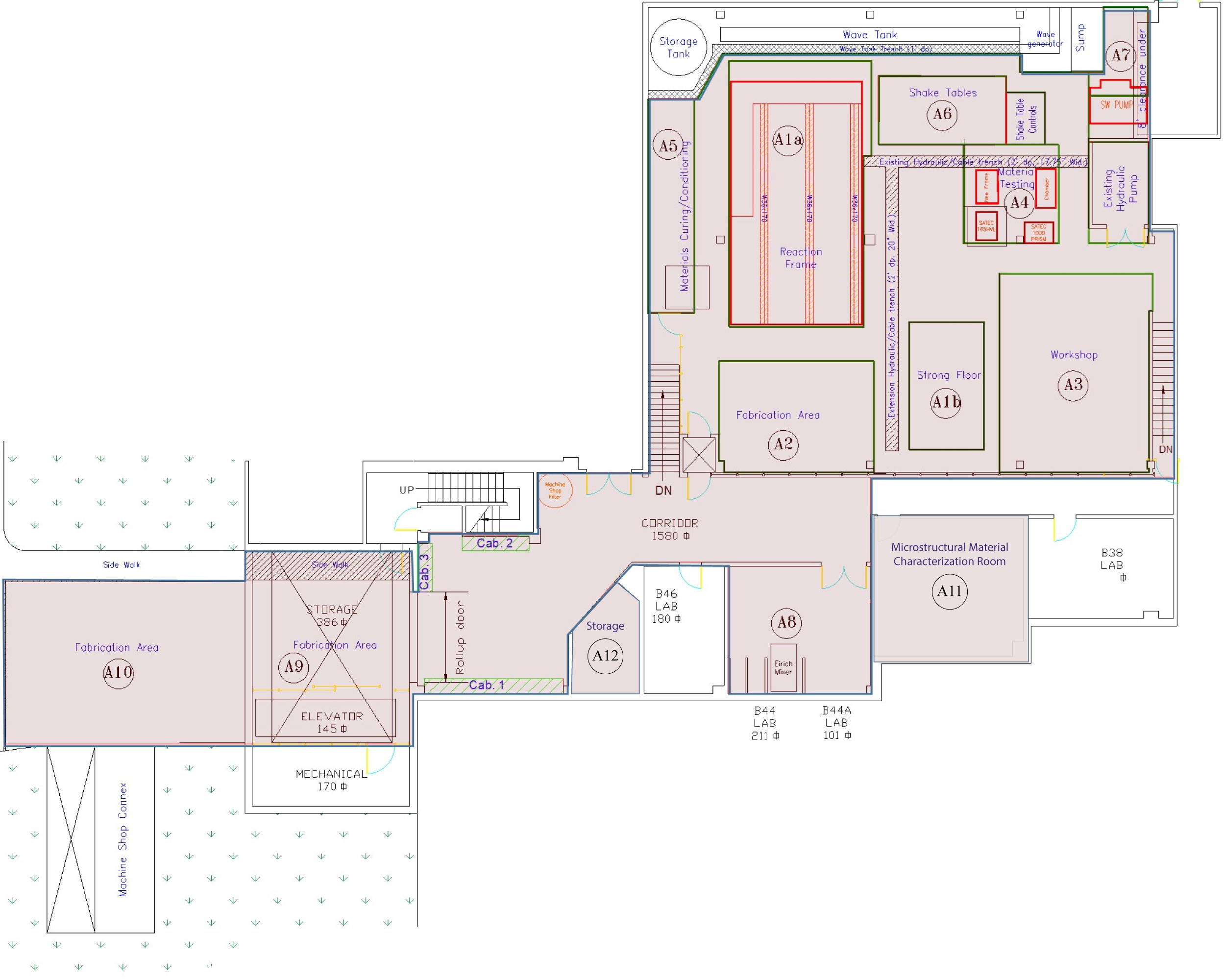

A floor plan of the laboratory is shown in the figure. One bay of the laboratory space (over A1a and A2) is served by a 5-ton overhead crane. Additionally, three forklifts with capacities of 5,800 lbs, 6,400 lbs and 3,000 lbs are available. As indicated in the figure the laboratory space is divided into ten designated areas each of which houses various pieces of equipment for fabrication, and materials and structural testing: (A1a) Large-scale reaction frame, (A1b) Reduced-scale reaction frame, (A2) Indoor fabrication space, (A3) Workshop, (A4) Materials testing space, (A5) Materials curing/conditioning space, (A6) Shake tables, (A7) Hydraulic power supply, (A8) Concrete materials room, (A9) Covered outdoor fabrication area and storage, and (A10) Outdoor fabrication area and storage, (A11) Microstructural material characterization room, (A12) Storage. A description of the use of and equipment housed in each one of these areas is provided in the following. In addition to these facilities, there is a wide range of sensors, data acquisition systems and other mobile devices for testing and characterization, as described below.